Hybrid High Frequency Printed Circuit Boards 3-Layer Hybrid RF PCB Made On 13.3mil RO4350B and 31mil RT/Duroid 5880

(PCBs are custom-made products, the picture and parameters shown are just for reference)

Introduction

Hello Everyone,

Warm greetings!

Today, we will discuss hybrid PCBs, which can consist of a combination of FR-4 and high-frequency materials, or a blend of different high-frequency materials with varying dielectric constants (DK), such as RT/Duroid 5880 and RO4350B.

This article focuses on a specific type of mixed high-frequency PCB constructed from 13.3mil (0.338mm) RO4350B and 31mil (0.787mm) RT/Duroid 5880, designed for multi-coupler antenna applications.

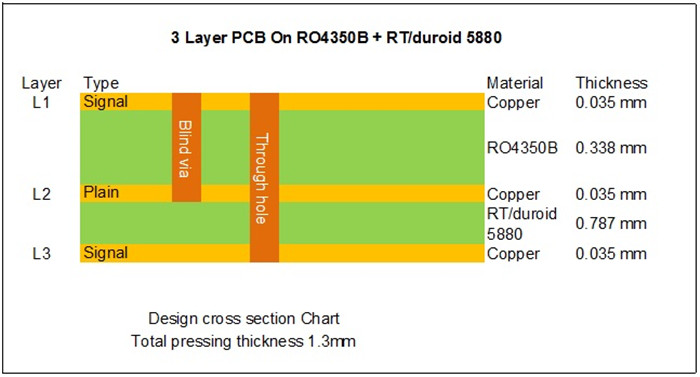

This is a 3-layer board that one layer is etched off.

Basic Specifications:

| Basic Specifications | Description |

|---|---|

| Base Material | RO4350B 13.3mil (0.338mm) + RT/Duroid 5880 31mil (0.787mm) |

| Dielectric Constant | 3.48 ± 0.05 |

| Layer Count | 3 layers |

| Via Type | Through holes, blind vias |

| Format | 160mm x 90mm = 1 type = 1 piece |

| Surface Finish | Immersion gold |

| Copper Weight | Outer layer 35μm |

| Solder Mask / Legend | Green / White |

| Final PCB Height | 1.3 mm |

| Standard | IPC 6012 Class 2 |

| Packing | 20 panels per shipment |

| Lead Time | 20 working days |

| Shelf Life | 6 months |

Features and Benefits

1.Lowest Electrical Loss: Reinforced PTFE material ensures minimal signal loss.

2.Enhanced Electrical Performance: Optimized for high-frequency applications.

3.Large Workshop Capacity: 16,000 square meters dedicated to PCB manufacturing.

4.Production Capability: 30,000 square meters of production capacity per month.

5.Diverse Product Range: Capability to produce 8,000 types of PCBs monthly.

6.Extensive Experience: Over 17 years in the PCB industry.

Applications

Point-to-Point Digital Radio Antennas

WiFi Amplifiers

Tower-Mounted Boosters

Power Amplifiers

RF Modules

Properties of RT/Duroid 5880

RT/duroid 5880 Typical Value |

||||||

Property |

RT/duroid 5880 |

Direction |

Units |

Condition |

Test Method |

|

Dielectric Constant,εProcess |

2.20 |

Z |

N/A |

C24/23/50 |

1 MHz IPC-TM-650 2.5.5.3 |

|

Dielectric Constant,εDesign |

2.2 |

Z |

N/A |

8GHz to 40 GHz |

Differential Phase Length Method |

|

Dissipation Factor,tanδ |

0.0004 |

Z |

N/A |

C24/23/50 |

1 MHz IPC-TM-650 2.5.5.3 |

|

Thermal Coefficient of ε |

-125 |

Z |

ppm/℃ |

-50℃to 150℃ |

IPC-TM-650 2.5.5.5 |

|

Volume Resistivity |

2 x 107 |

Z |

Mohm cm |

C/96/35/90 |

ASTM D 257 |

|

Surface Resistivity |

3 x 107 |

Z |

Mohm |

C/96/35/90 |

ASTM D 257 |

|

Specific Heat |

0.96(0.23) |

N/A |

j/g/k |

N/A |

Calculated |

|

Tensile Modulus |

Test at 23℃ |

Test at 100℃ |

N/A |

MPa(kpsi) |

A |

ASTM D 638 |

1070(156) |

450(65) |

X |

||||

860(125) |

380(55) |

Y |

||||

Ultimate Stress |

29(4.2) |

20(2.9) |

X |

|||

27(3.9) |

18(2.6) |

Y |

||||

Ultimate Strain |

6 |

7.2 |

X |

% |

||

4.9 |

5.8 |

Y |

||||

Compressive Modulus |

710(103) |

500(73) |

X |

MPa(kpsi) |

A |

ASTM D 695 |

710(103) |

500(73) |

Y |

||||

940(136) |

670(97) |

Z |

||||

Ultimate Stress |

27(3.9) |

22(3.2) |

X |

|||

29(5.3) |

21(3.1) |

Y |

||||

52(7.5) |

43(6.3) |

Z |

||||

Ultimate Strain |

8.5 |

8.4 |

X |

% |

||

7.7 |

7.8 |

Y |

||||

12.5 |

17.6 |

Z |

||||

Moisture Absorption |

0.02 |

N/A |

% |

0.62"(1.6mm) D48/50 |

ASTM D 570 |

|

Thermal Conductivity |

0.2 |

Z |

W/m/k |

80℃ |

ASTM C 518 |

|

Coefficient of Thermal Expansion |

31 |

X |

ppm/℃ |

0-100℃ |

IPC-TM-650 2.4.41 |

|

Td |

500 |

N/A |

℃ TGA |

N/A |

ASTM D 3850 |

|

Density |

2.2 |

N/A |

gm/cm3 |

N/A |

ASTM D 792 |

|

Copper Peel |

31.2(5.5) |

N/A |

Pli(N/mm) |

1oz(35mm)EDC foil |

IPC-TM-650 2.4.8 |

|

Flammability |

V-0 |

N/A |

N/A |

N/A |

UL 94 |

|

Lead-free Process Compatible |

Yes |

N/A |

N/A |

N/A |

N/A |

|

For further inquiries and detailed specifications, please feel free to contact us regarding your PCB needs. Feel free to adjust any specific terms or details as necessary!